Home » Shop » Veige Catalyst™ »

Veige Catalyst™ 1

FREE SHIPPING

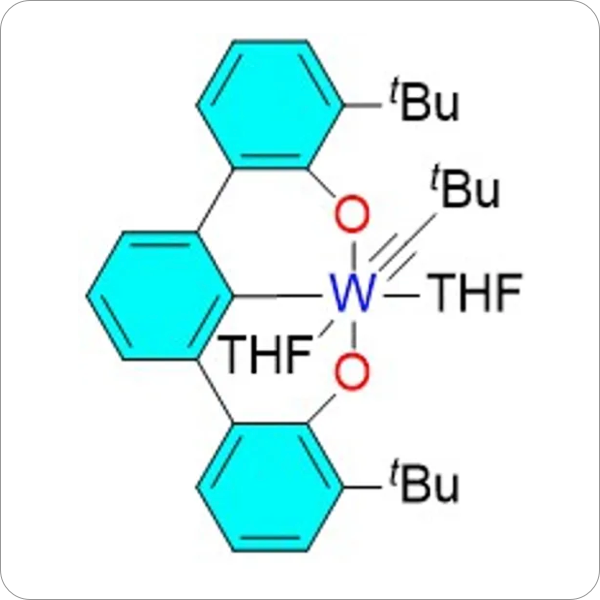

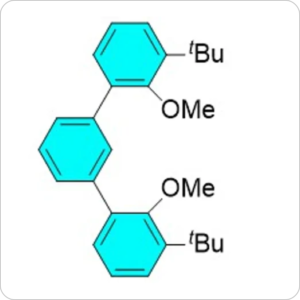

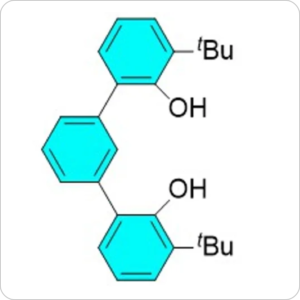

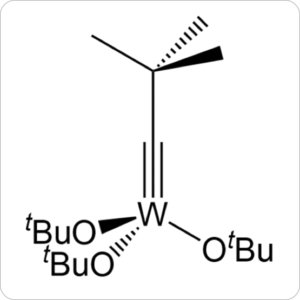

OCO-Trianionic-pincer tungsten(VI)-tert-butyl-alkylidyne Veige Catalyst™. IUPAC Name: (2,2-dimethylpropylidyne)bis(tetrahydrofuran); [3,3′-bis(1,1-dimethylethyl)[1,1′:3′,1”-terphenyl]-2,2”-diolato(3-)-κC²’,κO²,κO²”]tungsten

Description:

The trianionic pincer tungsten-alkylidyne Veige Catalyst™ is used in the synthesis of cyclic polymers. The Veige Catalyst™ will polymerize alkynes to produce cyclic polyacetylenes. The metal-carbon bond coupled with a strained trianionic pincer ligand creates a highly reactive complex that will react with most unsaturated substrates. The ligands are specifically designed to provide a unique coordination environment, influencing the molecule’s properties and potential applications. The presence of tetrahydrofuran ligands further enhances its solubility and compatibility in organic solvents, expanding its applicability in diverse chemical processes.

Applications:

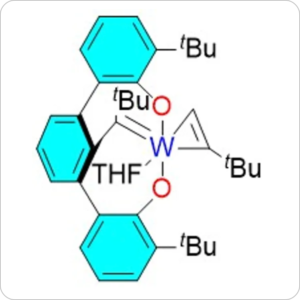

The distinctive structure of the Veige Catalyst™ makes it a promising candidate for various catalytic applications. The trianionic pincer tungsten-alkylidyne Veige Catalyst™ is used as catalyst for the synthesis of cyclic polymers. The Veige Catalyst™ will polymerize alkynes to produce cyclic polyacetylenes. The Veige Catalyst™ can also be converted into a series of second-generation catalysts by treating with a variety of unsaturated substrates including bulky alkynes, organoazides, carbon dioxide, isocyanates, carbon disulfide among others. The metal-carbon triple bond is highly reactive and will insert into the pincer backbone readily affording a tethered alkylidene. The Veige Catalyst™ will also polymerize cyclic alkenes via ring expansion metathesis polymerization (REMP). With its well-defined coordination environment and tunable reactivity, this complex enables the creation of novel cyclic polymers with tailored properties such as mechanical strength, thermal stability, and chemical resistance. Applications span diverse fields including advanced composites, coatings, adhesives, conductive polymers, packaging, and elastomers.