A New Era for Polymers Without Ends

The polymer industry has always moved forward on the back of catalyst innovation — and the next major leap is here. After decades of theoretical promise, cyclic polymers are finally reaching commercial-scale production thanks to a breakthrough tungsten-based catalyst discovered by Professor Adam Veige and his team at the University of Florida.

This catalyst — now commercialized by Oboro Labs — makes it possible to efficiently polymerize alkynes directly into polymers with no chain ends, unlocking performance and sustainability advantages that were previously out of reach.

Why This Breakthrough Matters

For over 50 years, researchers could only synthesize cyclic polymers in tiny milligram quantities, bottlenecking any real-world testing. Veige Catalyst™ changes the equation entirely:

- Output measured up to 180 million g/mol/hr, reaching commercial-scale productivity.

- Catalyst synthesis has been scaled from grams to hundreds of grams per batch.

- Cyclic polyethylene, polypropylene, polystyrene, polynorbornene, and polyacetylene are now available for customer trials and compounding.

Oboro Labs can now supply both the catalyst itself and finished cyclic polymers — a milestone the industry has waited for.

Performance Benefits: Why Cyclic Polymers Are Different

Removing chain ends does more than change polymer structure — it dramatically shifts polymer behavior:

1. Higher Glass-Transition Temperatures

Chain ends act as the first points of thermal motion in linear polymers. Without them, cyclic polymers require more energy to flow, giving them better high-temperature performance.

2. Better Performance at Lower Molecular Weights

“A lower-molecular-weight cyclic polymer can perform like a higher-molecular-weight linear polymer,” explains Jason Stiel, VP of Sales at Oboro.

That means lighter materials, improved sustainability, and reduced cost.

3. Improved Degradation Resistance

Cyclic polymers delay the onset of thermal and shear degradation — crucial for:

- Extrusion processing

- Multi-cycle recycling

- High-stress applications

- Synthetic oils and viscosity modifiers

A polymer without ends simply wears out slower.

4. Fewer Defects = Better Electrical Performance

A University of Houston study showed cyclic polystyrene capacitors achieve significantly higher breakthrough voltage.

Linear polymers contain billions of chain ends — each a possible defect site. Removing them enhances dielectric strength and energy storage capacity.

5. Emerging Application Advantages

Research and customer testing point toward benefits including:

- Higher electrical conductivity

- Antifouling behavior

- Lower surface friction

- Higher crystallization rates

- Reduced melt viscosity

Industry response has been strong, with multiple partners now running independent trials on Oboro’s materials.

Commercialization Begins — Oboro Labs Leads the Charge

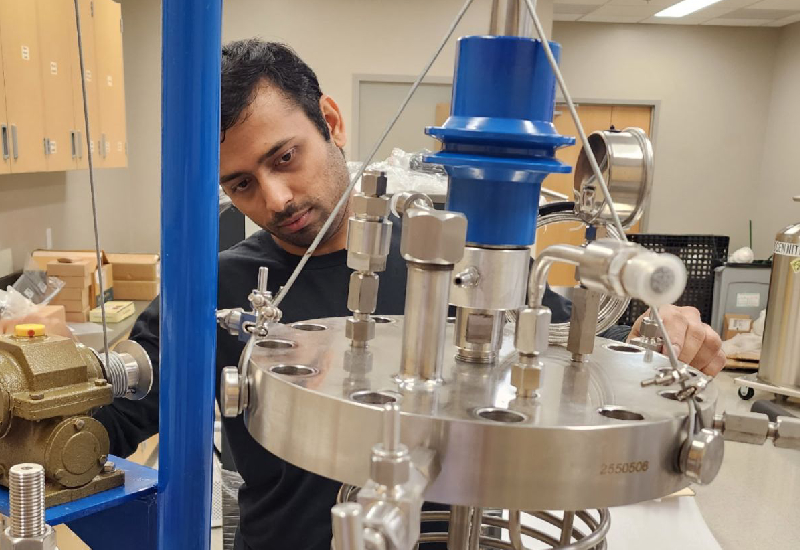

With support from the National Science Foundation, fundamental research has transitioned to real-world capability. Oboro Labs now operates a custom laboratory facility dedicated to scaling, producing, and supplying this world-first family of cyclic polymers.

CEO Greg Kis notes that industry interest has been “terrific,” with leading companies testing cyclic polymers for next-generation materials, electronics, additive manufacturing, and recyclability-focused product lines.

Oboro Labs is now positioned as the first company to bring cyclic polymers to market at meaningful scale, setting the stage for a new chapter in polymer science.

Explore our online portfolio or contact us today for more information.

Source Citation

This article summarizes and references reporting from:

A New Beginning for Polymers Without Ends, Plastics Technology Online, available at: https://www.ptonline.com/articles/a-new-beginning-for-polymers-without-ends

Additional Scientific Reference

Enhanced Dielectric Strength and Capacitive Energy Density of Cyclic Polystyrene Films,

ACS Polymers Au (2022), University of Houston.

This study demonstrated that cyclic polystyrene exhibits significantly higher dielectric breakdown strength and energy storage capacity compared to linear analogs, supporting the performance advantages discussed in this article.

DOI: https://doi.org/10.1021/acspolymersau.2c00014